What is overwrapping machine?

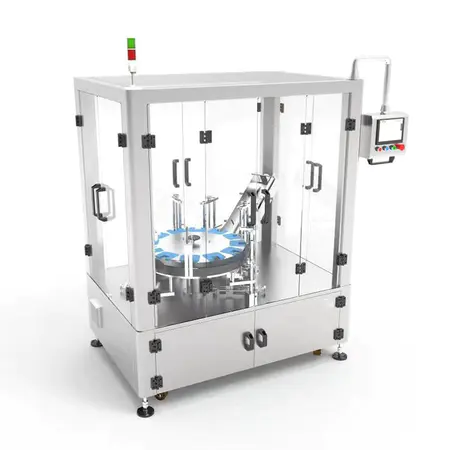

An overwrapping machine, also known as a cellophane wrapping machine or a wrapping system, is a specialized packaging equipment used to wrap products with a protective and visually appealing outer layer. It is commonly employed in industries such as food and beverage, cosmetics, pharmaceuticals, and consumer goods. The overwrapping process involves encasing the product in a heat-sealed transparent film, typically made of cellophane, polypropylene, or polyethylene. This film tightly conforms to the shape of the product, providing protection against dust, moisture, tampering, and preserving the product's freshness.

PRODUCTION ADVANTAGE

We specialize in packaging machine for 20 years, we meet the needs of customers of various specifications and best-selling in world market by stable quality and factory price.

SERVICE ADVANTAGE

We have a 10-year marketing team, one to one after-sales service for all customers.

DELIVERY ADVANTAGE

our machines are very popular at home and abroad, we have some standard equipment in stock, customize machine normally delivery in advance, we have our own professional transport chain.

Related Products

More items about overwrapping machine

We Have The Best Solutions for Your Business

Wenzhou Tuoyi Machinery Co., Ltd. is a technological machinery enterprise integrating R&D, manufacturing and sales. ave a group of experienced machinery R&D and sales teams.

Our main products are capping machine, cartoning machine, cellophane wrapping machine, film packaging machine, film wrapping machine, food cartoning machine, horizontal cartoning machine, labeling machine, liquid filling machine, overwrapping machine, pharmaceutical cartoning machine, sealing machine, shrink packaging machine, shrink wrap machine, shrink wrapping machine, sticker labeling machine, wine labeling machine,. If you are interested in that, please contact us for more information.

Cost Savings and Sustainability

By automating the packaging process, overwrapping machines help reduce labor costs and increase overall operational efficiency. The precise use of film materials minimizes waste and lowers material costs. Additionally, overwrapping machines can use recyclable and eco-friendly films, contributing to sustainable packaging practices.

Extraordinary

The machine has fast packaging speed, stable operation and fast variety replacement. It can carry out automatic packaging, with frequency conversion speed regulation, fault alarm, machine jog adjustment, and counting functions. The packaged product is smooth and beautiful, improves the product grade, has firm sealing, good sealing, anti-counterfeiting, moisture-proof and easy to unpack.

Product advantages

1.The structure is compact and reasonable, the performance is stable and advanced, and the operation is simple and easy to understand;

2.The host adopts frequency conversion speed regulation (the number of packaging can be from 30 boxes to 120 boxes/min, and the corresponding number of times can be set according to the difficulty of the packaging items and the packaging box);

3.PLC automatic control system.

Integration with Existing Production Lines

Overwrapping machines can be seamlessly integrated into existing production lines, providing a smooth transition and enhancing overall workflow. These machines can be synchronized with upstream and downstream equipment, such as filling machines or labeling systems, to create an efficient and fully automated packaging process.

Frequently Asked Question

Do you have any question?

1. Pay attention to the size of the packaging material2. Pay attention to the function of the packaging machine3. Need to pay attention to the additional problems of the packaging machine

Equipped with an automatic detection system, and alarm, reject, and locate and stop unqualified products.Automatic shutdown due to mechanical overload.

Get In Touch

Don't hesitate to contact with us

- film packaging machine

- cartoning machine

- labeling machine

- capping machine

- sealing machine

- shrink wrap machine

- shrink wrapping machine

- shrink packaging machine

- film wrapping machine

- sticker labeling machine

- liquid filling machine

- overwrapping machine

- cellophane wrapping machine

- food cartoning machine

- horizontal cartoning machine

- wine labeling machine

- pharmaceutical cartoning machine